Air Flow Dryer

Last update 2022-07-06

Application

MKAD air dryer is widely applied in the fields of requiring fast drying and heat sensitive powder or slice material such as corn/wheat/potato/cassava starch, protein flour, rice bran, calcium carbonate, diatomite, colophony, paint, glucose, sawdust, ferric oxide, aluminum hydroxide and residuals like filtrate cake which is not too much powder in light industry, chemical industry and foodstuff, etc.Gluten ring dryer can be used to dry the wheat vital gluten.

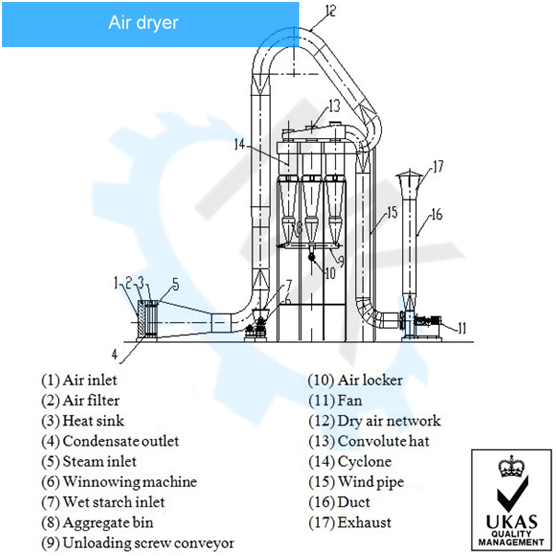

Description

Air dryer is the ideal equipment for drying the end products like starch, modified starch and wheat gluten in starch industry. Starch dried by this equipment features in clean appearance, glossy luster, smooth powder, and stable moisture while wheat gluten

features in high water absoption, excellent activity and original flavor. this equipment can be designered and procuced based on customers' requests on space and warehouse, which is convenient for installation, operation and maintenance.

Air speed

is continuously changed because of different section diameters of pulse tubes, therefore, heat transfer coefficient is high and massmaterials can be dried well. Ring-type air flow dryer is especially designed for wheat gluten and B starch, which could

ensure complete dryness and product refining.

This equipment features in simple structure, easy operation, low investment, as well as compactness. 1.8-2.0 tons of steam will be needed for evaporating 1 ton of water.

Working principle

Sludge, powder and granular material are in the state of suspension under the effect of high-speed hot air. As flow speed is high, the material particles suspended in air, the heat transfer surface and heat transfer coefficient of gas-solid is high, and

drying time is short (most of the dry material only a few seconds), it is particularly suitable for drying of heat sensitive materials.

During the drying process, clean the air heater through the cold air from the wet starch after delivering

the transport auger feeder into the air duct by the young wet starch mixture, are instantly dry, dry starch cyclone, discharging auger off air control exhaust, emissions into the atmosphere by the fan.

The machine can be controlled, both manual

and automatic operation. When it is by automatic control, the exhaust gas temperature of automatic measure by water controlled will send back the signal to the previous feeding adjustable motor. By this way, the feeding capacity can be controlled.

Also the output moisture content will be ensured.

Structure

Characteristics

1. Using air instant drying principle, with the characteristics of high drying intensity.

2. Short drying time, low steam consumption and fast dewatering

3. High thermal efficiency and excellent quality of dried products;

4. High drying intensity

and strong dewatering ability;

5. Simple structure, small area occupied and low investment

6. Negative pressure environment, clean and no pollution.

Main technical specification

| 型号Model |

进料淀粉湿度Moisture of wet starch |

出料淀粉湿度Moisture of product starch |

淀粉产量Starch capacity(t/h) |

功率Power(kw) |

|---|---|---|---|---|

| MKAD-0.5 |

≤40% |

12-14% | 0.5 |

21.3 |

| MKAD-0.8 | ≤40% | 12-14% | 0.8 |

24.3 |

| MKAD-1 | ≤40% | 12-14% | 1 |

26.6 |

| MKAD-1.2 | ≤40% | 12-14% | 1.2 |

30.1 |

| MKAD-1.6 | ≤40% | 12-14% | 1.6 |

40.6 |

| MKAD-2 | ≤40% | 12-14% | 2 |

47.6 |

| MKAD-2.6 | ≤40% | 12-14% | 2.6 |

59.5 |

| MKAD-3.2 | ≤40% | 12-14% | 3.2 |

75 |

| MKAD-3.6 | ≤40% | 12-14% | 3.6 |

95 |

| MKAD-5 | ≤40% | 12-14% | 5 |

123.4 |

| MKAD-6 | ≤40% | 12-14% | 6 |

170 |

| MKAD-10 | ≤40% | 12-14% | 10 |

223.5 |

| MKAD-15 | ≤40% | 12-14% | 15 |

321 |

| MKAD-20 | ≤40% | 12-14% | 20 |

420 |

Site photo