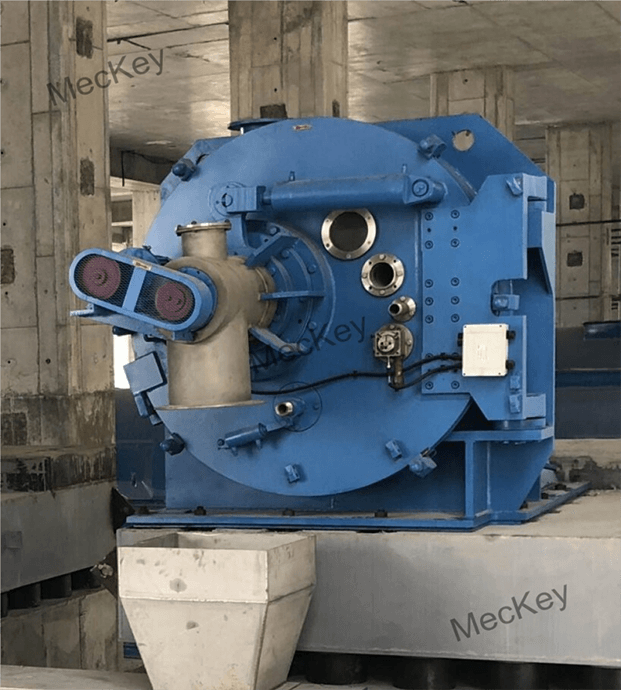

Peeler Centrifuge

Last update 2022-05-27

Application

MKPC series Peeler centrifuge is the main equipment used in purified starch slurry dewatering before final drying to commercial product.

Description

1.Peeler centrifuge Structure: This centrifuge mainly consists of scraper, case and door cover assembly, rotating bashet assembly, driving system, hydraulic system, electric system and so on. The frame assembly is a supporting part, which is composed of base, casing, bearing box and rear plate. Rotating basket assembly is a rotating part, which has rotating basket, main shaft, bearing and driven belt pulley. The rotating basket is supported inside the case through a snspended arm. The door cover is at the front of the case, which installed with scraper, feed tube, washing tube and unloading hopper. The hydraulic system is installed outside separately. There is a hydraulic coupler on the main motor, which is connected with drive belt pully through V belt. The electric controll system is an independent part that can be installed at the convenient place.

2.Peeler centrifuge Working principle: Open the feed valve when the machine works at full speed. The suspension to be separated is fed into the rotating basket and distributed on the filter medium equally. The liquid phase is drained outside the rotating basket through the filter medium and the hole on the basket under the centrifugal force. Meanwhile, the solid phase is held on the filter medium and become sediment. Close the feed valve when the sediment coat reaches a certain thickness. At the same time, open the washing valve, wash the solid phase and dry it. At last, unloading the sediment coat by rotating scraper and discharge through unloading hopper.

Characteristics of the equipment

1.The peeler centrifugal is made of stainless steel to prevent starch pollution;

2.The peeler centrifugal surface is treated in a special process, beautiful and oil & dirt resistance;

3.The wet starch output from peeler centrifugal are low moisture and high yield.

4.The device features simple and reasonable design, beautiful appearance and stable quality, easily maintenance.

Main technical specification

| Model | MKPC800N | MKPC1250N | MKPC1600N |

| Basket length(mm) | 450 | 600 | 1000 |

| Rotating speed of basket(rpm) | 1550 | 1200 | 950 |

| Filtering Area(㎡) | 1.13 | 2.36 | 4.98 |

| Loading limit(kg) | 150 | 450 | 996 |

| Loading Volume(L) | 100 | 355 | 830 |

| Separating Factor | 1070 | 1006 | 799 |

| Main motor power(kW) | 45 | 90 | 132 |