Maltose / Dextrose Syrup

Last update 2022-05-27

Glucose Producing Technology

Glucose producing technology

All kinds of starch sugar will be got by starch hydrolysis with acid or enzyme. The liquid products are maltose, glucose syrup, fructose syrup; The solid products are monohydrate dextrose, anhydrous dextrose, crystal fructose, maltodextrin, etc. They are mainly used as a sweetener in food industry. Anhydrous dextrose can be used as medical injection, tablet embedding medium, sweeteners for medicinal syrup. Glucose and maltose can produce sorbitol and maltitol by hydrogenation, which are used in the food and toothpaste to prevent dental caries. In addition, the polyols can lead starch glucose products into petroleum field.

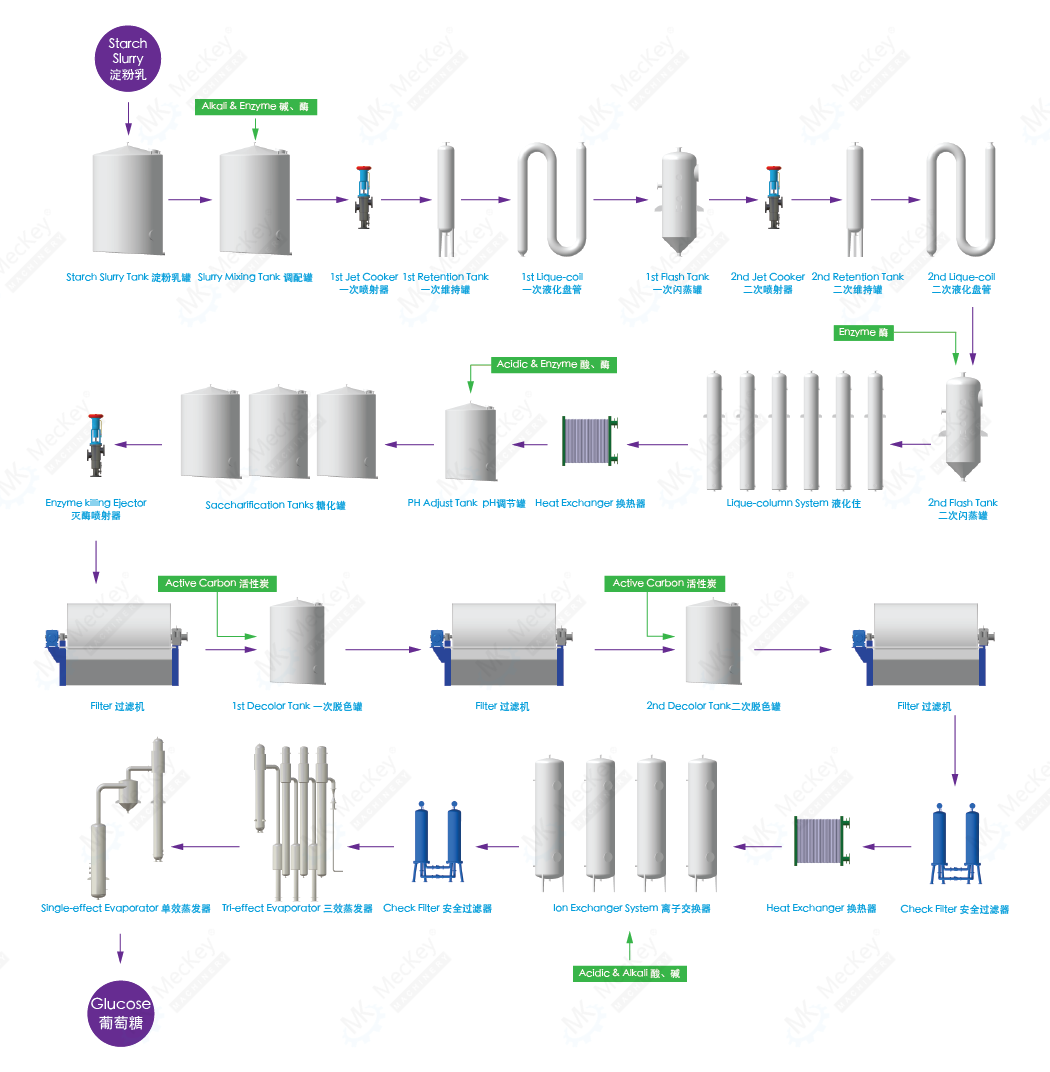

(1) Starch milk adjustment: The DS value of the starch that came from starch plant is adjusted to 28-32% and control a proper value of PH and temperature. Or adding a certain amount of water to achieve the above conditions then go to the next section.

(2) Liquefaction: Starch milk is sent to buffer tank then liquefied through jet cooker and liquefaction column by amylase.

(3) Saccharification: The liquefied liquid keeps reaction for a certain time under the action of enzyme. Then the required DE value of the glucose will be produced. The glucose is sent to the enzyme killer to make the enzyme in active.

(4) Filtration and decolorization: Glucose gets cleaned through the filter to remove protein and other impurities, then at the appropriate temperature passes by active carbon to decoloring, finally send to filters to remove activated carbon and then send to the next section.

(5) Deionizaiton: The filtrate is sent to ion exchanger after filtration and decoloring, the inorganic salt, soluble impurities and bad order will be removed by cation and anion resin, then the purified glucose is sent to evaporator.

(6) Evaporation: The glucose is totally cleaned through safety filter machine then sent to evaporator for concentrating to reach the required DS as final product.

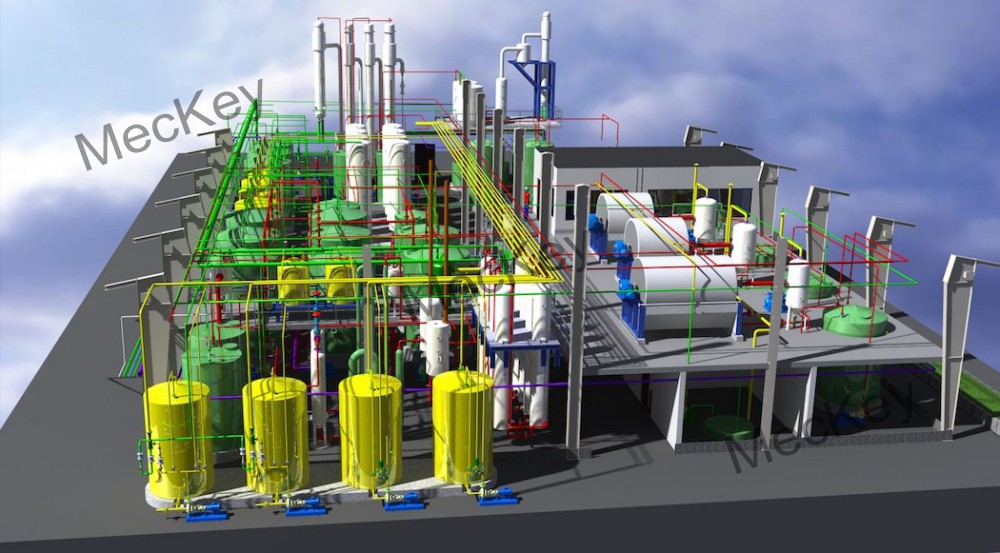

Project 3D design