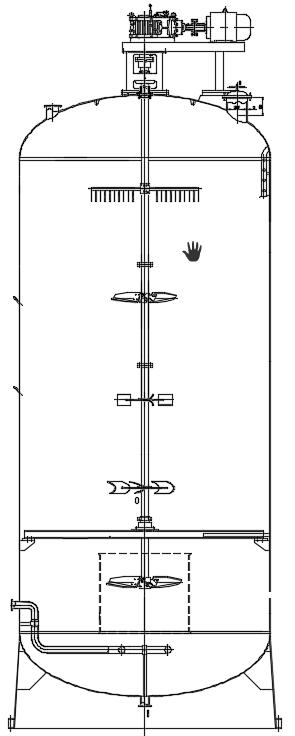

Fermentation Tank

Last update 2022-07-06

Description

Fermentation tanks are widely used in dairy products, beverages, biological engineering, pharmaceuticals, fine chemicals and other industries. The tank body is equipped with interlayer, insulation layer, heating, cooling, and insulation. Both the tank body and the upper and lower filling heads (or cones) are processed by spinning R angles. The inner wall of the tank is mirror-polished, so there is no sanitary dead corner. The fully enclosed design ensures that the materials are always mixed and fermented in a pollution-free state. Equipment is equipped Air breathing hole, CIP cleaning nozzle, manhole and other devices.

Structure

Main Technical Specification

| Model | Nominal capacity(m3) | Diameter(mm) | Heright(mm) | Heat exchange are(m2) | Rotation speed(rpm) | Power(kW) |

|---|---|---|---|---|---|---|

| MKFT-10 | 10 | 1800 | 3800 | 14 | 160-260 | 17-22 |

| MKFT-20 | 20 | 2200 | 5000 | 22 | 160-260 | 30-37 |

| MKFT-40 | 40 | 2600 | 7500 | 45 | 150-250 | 55-75 |

| MKFT-60 | 60 | 3000 | 8300 | 65 | 150-250 | 65-115 |

| MKFT-100 | 100 | 3600 | 9400 | 114 | 150-250 | 120-125 |

| MKFT-200 | 200 | 4600 | 11500 | 220 | 140-240 | 215-360 |

| MKFT-400 | 400 | 6200 | 13300 | 450 | 100-150 | 280-360 |

| MKFT-600 | 600 | 7200 | 14800 | 680 | 100-150 | 450-500 |

| MKFT-800 | 800 | 8000 | 16000 | 960 | 100-150 | 500-600 |