Sorbitol

Last update 2022-05-27

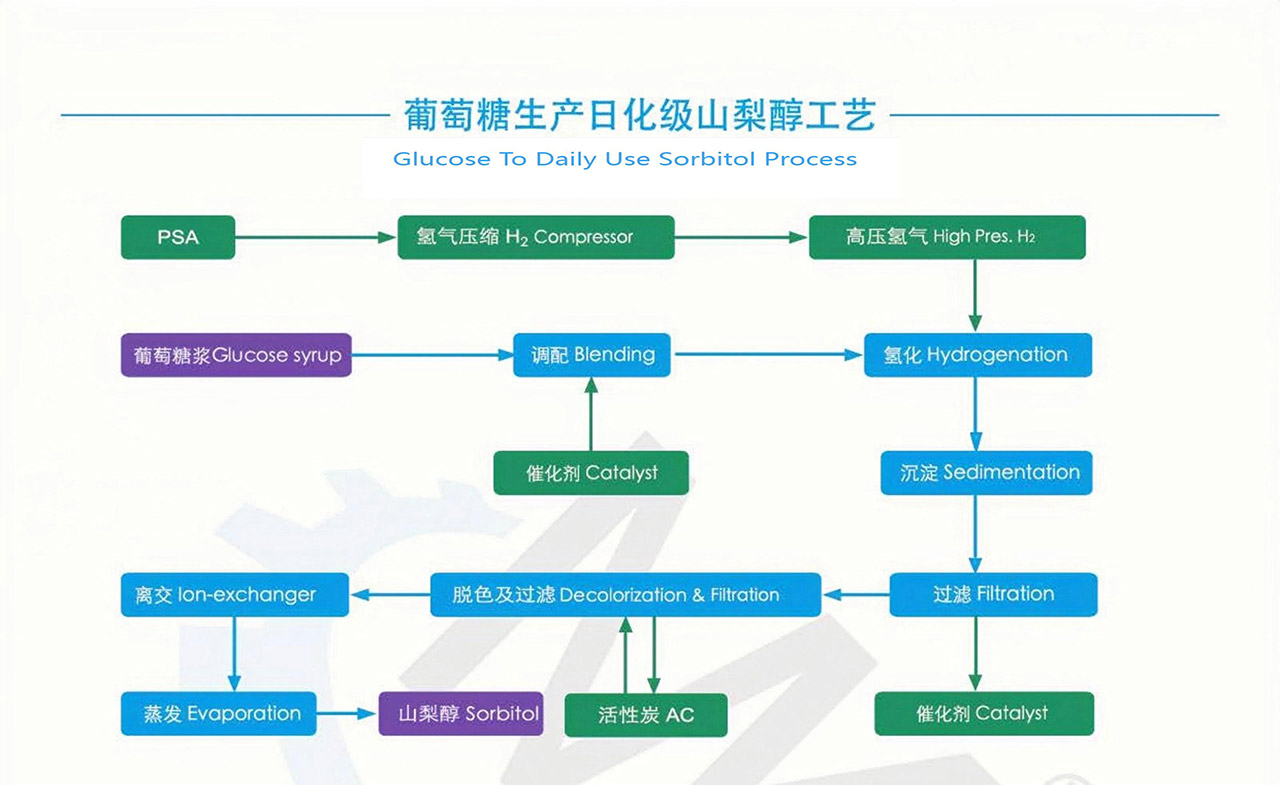

Process of sorbitol

(1) Blending: Adjusting concentration of dextrose syrup to 45-50% by R.O water, then adding alkali to maintain ph value, after that adding catalyst.

(2) Hydrogenation: Pump the prepared dextrose syrup into reactor, then heating and continous feeding hydrogen gas into reactor for reaction. The dextrose will be converted to sorbitol under suitable temperature, presuure and a certain of time.

(3) Sedimentation: The crude sorbitol solution is sent to settling tank for catalyst sedimentation and recovery.

(4) Filtration: After precipitation, the sorbitol solution needs to be filtered to remove the residual catalyst.

(5) Decolorization: Remove the colored substances in sorbitol solution by active carbon.

(6) Ion exchange: Remove the salt and organic existing in the sorbitol solution by the ion exchange resin to improve the quality of the product.

(7) Evaporation: Increase the concentration of sorbitol solution by evaporation to meet the concentrate requirement of product.