Decanter/Tricanter

Last update 2022-07-06

1.Decanter

Application

MKLW Decanter are widely used for wheat A & B starch refining and concentration, corn gluten concentration, waster water treatment, etc..

Description

Decanter centrifuge is a mechanical equipment which utilize the principle of centrifugal and sedimentation and can carry out continual separate the suspend liquid with density difference. The centrifuges which made by our factory can clarify, dehydrate and classify the suspensions with 0.002-3 mm solid-phase particles and thickness range at 0.5-40%. The product can be classify into two type LW counter-current and parallel-current base on its structure feature. According to feed feature, product can be divide into LW two-phase separator, LWS three-phase separator. It is suitable for separating different feed under different process condition, and widely use in pharmaceutical, food, chemical, light industry, environmental protection industry etc..

LW type decanter centrifuge utilize the specific gravity difference of object, make the solid-phase subside under the centrifugal force. There is a fraction of filter screen on the solid outlet port, when screw dry, the liquid through the filter screen rapidly, thus the solid can be done further dehydration before discharge. So that make the discharged solid more dry and liquid much clearer. It is especially suitable for the solid-liquid separation site which the liquid-phase needs the higher requirement.

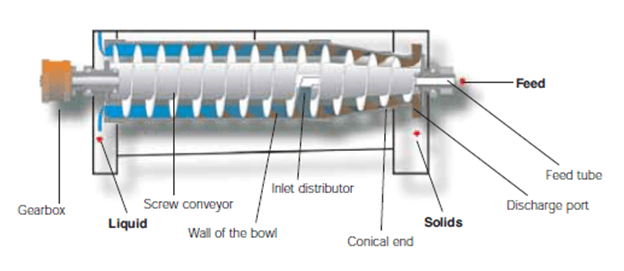

Production structure

Main body of decanter centrifuge are consist of column-taper drum, helical pusher, speed difference system, shaft seat, frame, enclose, main and auxiliary motor and electric system. Main motor drive drum, auxiliary motor drive planetary gear differential, so that create different speed between drum and screw, then carry on continual separation in 24 hours under the strong centrifugal force which produced by the high speed rotate of separator.

Operation principle

Drum and screw rotate at a certain different speed. The feed enters the drum through a stationary inlet tube and is accelerated smoothly by an inlet rotor. The resulting centrifugal forces make the solids collect on the wall of the drum. Screw conveyor continual moving the solid to conical end of drum, discharge through discharge port after dried in the dry area, however, light liquid forms the inner layer and effusion through overflow port of drum, then discharge through liquid outlet port.

Product characteristics

1. Helical pusher adopts the special antifriction method: sprinkle hardness alloy or inlay hardness alloy anti-friction disk; anti-corrosion stainless steel is employed for the material of the main parts of drum, so that assure the durability and longer using lifetime of the equipment.

2. According to the operating condition’s characteristics of material, optimize the drum length-diameter radio, drum and structure of drum taper parts.

3. According to the material thickness, flow change, the rotate speed difference and tolerance can be adjusted intelligently. During dehydration of the separator, if the thickness of input feed is changed, you can adjust the speed difference and tolerance of the drum and helix.

4. Select the planetary gear differentia with heavy load and large drive radio.

5. The separator occupied little area, easy to be assembly and commissioning; the whole machine is operated hermetically, and has a good production environment.

6. Adopt double frequency conversion control for main motor and differentia auxiliary motor, so make stepless speed regulation come true as well as enlarge the scope of application.

Main technical specification

| 型号Model |

MKDT420 |

MKDT480 | MKDT530 | MKDT580 | MKDT650 |

|---|---|---|---|---|---|

| 工作直径Drum diameter(mm) | 420 |

480 |

530 |

580 |

650 |

| 螺旋差转速Spiral difference rotate speed(可调Stepless)(r/min) | 1~30 |

1~30 | 1~30 | 1~30 | 1~30 |

| 分离因子Factor of separation(可调Stepless)(G) | Max. 3600 |

Max. 3700 | Max. 3700 | Max. 3500 | Max. 3500 |

| 转速Rotary speed(可调Stepless)(r/min) | Max. 3800 | Max. 3600 | Max. 3500 | Max. 3200 | Max. 3000 |

| 长径比Draw ratio L/D |

4.3 |

4.2 |

4.0 |

4.3 |

4.3 |

| 主电功率Power of main motor(Kw) |

37 |

45 |

55 |

75 |

110 |

| 辅助电功率Power of auxiliary motor(Kw) | 11 |

15 |

18.5 |

22 |

37 |

| 外形尺寸Dimension(mm) | 3600×940×1320 |

3955×1004×1400 | 4270×1380×1558 | 4770×1380×1558 | 4853×1460×1618 |

| 重量Weight(Kg) | 3000 |

4820 |

5600 |

6000 |

7000 |

2.Tri-canter

Application

MKLW Tricanter can be used for Processing of sludges containing oil from refineries & oil ponds, extracting animal/vegetable fats & oils, and separating wheat starch & gluten.

Description

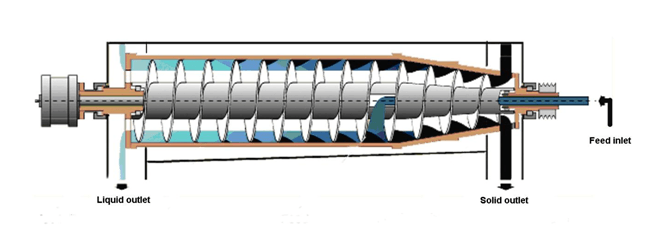

In three-phase separation, it is possible to separated two liquid phases from one solid phase at the same time. The MKLW Tricanter is the perfect partner for separating these three phases. The different densities of the (immiscible) liquids and the solid mean that all three phases can be discharged simultaneously using the Tricanter. This is the reason for the name Tricanter (tri for three).

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the liquid phases must have different densities. Otherwise, the scroll of the decanter will not be able to transport the solid at all, or only inadequately, and this has an affect on the separation result.

The structure and function of the Tricanter are similar to those of a decanter (two-phase separation). The decisive difference between these two machines concerns the way that the liquid is discharged. There are two liquid phases in a Tricanter. A "heavy" liquid phase (higher density and discharged under pressure) as well as a "light" liquid phase (lower density and discharged without pressure).

stable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

Main technical specification

| 型号Model |

MKTT420 |

MKTT480 | MKTT530 | MKTT580 | MKTT650 |

|---|---|---|---|---|---|

| 工作直径Drum diameter(mm) | 420 |

480 |

530 |

580 |

650 |

| 螺旋差转速Spiral difference rotate speed(可调Stepless)(r/min) | 1~30 |

1~30 | 1~30 | 1~30 | 1~30 |

| 分离因子Factor of separation(可调Stepless)(G) | Max. 3600 |

Max. 3700 | Max. 3700 | Max. 3500 | Max. 3500 |

| 转速Rotary speed(可调Stepless)(r/min) | Max. 3800 | Max. 3600 | Max. 3500 | Max. 3200 | Max. 3000 |

| 长径比Draw ratio L/D |

4.3 |

4.2 |

4.0 |

4.3 |

4.3 |

| 主电功率Power of main motor(Kw) |

37 |

45 |

55 |

75 |

110 |

| 辅助电功率Power of auxiliary motor(Kw) | 11 |

15 |

18.5 |

22 |

37 |

| 外形尺寸Dimension(mm) | 3600×940×1320 |

3955×1004×1400 | 4270×1380×1558 | 4770×1380×1558 | 4853×1460×1618 |

| 重量Weight(Kg) | 3000 |

4820 |

5600 |

6000 |

7000 |