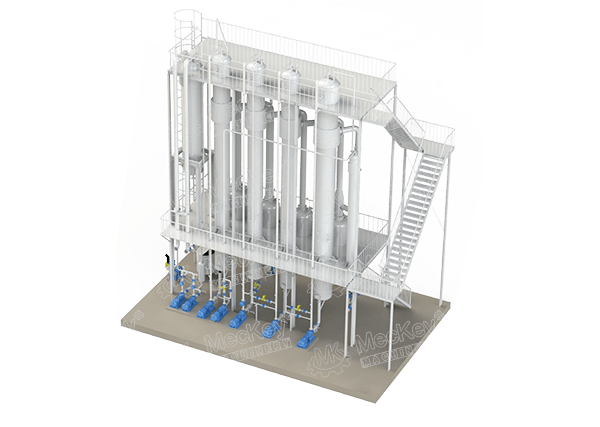

Tubular Evaporator

Last update 2022-05-27

Application

MKFE series multiple-effect falling film evaporator is widely used for concentrating corn slurry, glucose and maltose in starch industry, juice and MSG liquid in food industry, milk liquid in dairy industry, as well as lees filtrate in alcohol industry.

Description

MKFE series multiple-effect falling film evaporator concentrates the solution by means of vaporizing the thin solution through film-falling principle. It introduces continuous production and it features in high concentration ratio (1/5-1/10), large viscosity scope (400CP), good heat-transferring effect, large processing capacity, etc. In this case, it can be introduced on vaporizing materials which are of high heat sensibility, high concentration, high viscosity, and corrosive characteristics. Therefore, it is widely used. This equipment is of higher heat-transferring ratio, so the heat difference requested is small. It can be combined into double, triple, quadruple, or quintuple-effect evaporating system on the basis of different material characteristics and evaporating results. In addition, it can be used as waste-heat evaporator with the resources of waste steam from bundle dryer, disc dryer or other heat resources with low thermal value such as condensate steam. In this way, raw steam consumption can be greatly reduced for energy saving. It is economically beneficial when waste steam can be completely used and raw steam is saved.

Characteristics of the equipment

1.High yield and energy-saving.

2.Customized design to meet customers’ various demands;

3.The equipment surface is treated in a special process, beautiful and oil & dirt resistance;

4.The device features simple and reasonable design, beautiful appearance and stable quality, easily maintenance.

Main technical specification

| Model | MKTE3 | MKTE6 | MKTE9 | MKTE10 | MKTE12 | MKTE15 | MKTE20 | MKTE30 | MKTE40 | MKTE50 | MKTE60 |

| Max evaporation(kg/h) | 3000 | 6000 | 9000 | 10000 | 12000 | 15000 | 20000 | 30000 | 40000 | 50000 | 60000 |

| Steam pressure(MPa) | 0.6~1.0 | ||||||||||

| Steam consumption(kg/h) | 900 | 1500 | 2000 | 2300 | 2600 | 3300 | 4200 | 6000 | 8000 | 10000 | 12000 |

| Input DS(%) | 6~7(Steeping liquid); 26~30(Glucose syrup); 9~11.5(liquid milk) | ||||||||||

| Output DS(%) | 42~48(Steeping liquid); 70~75(Glucose syrup); 45(liquid milk) | ||||||||||

| Vacuum degree(MPa) | 1st effect | 0.01~0.03 | |||||||||

| 2nd effect | 2nd effect | 0.03~0.05 | |||||||||

| 3rd effect | 3rd effect | 0.05~0.07 | |||||||||

| 4th effect | 4th effect | 0.07~0.09 | |||||||||

| Evaption temp(℃) | 1st effect | 90~110 | |||||||||

| 2nd effect | 2nd effect | 75~85 | |||||||||

| 3rd effect | 3rd effect | 65~75 | |||||||||

| 4th effect | 4th effect | 50~60 | |||||||||

Site photo