Pin Mill

Last update 2022-05-27

Application

The pin mill is widely used to corn, potato, starch and other industries. It has many advantages such as simplifying the process of production of starch, improving the rate of collection of starch and having outstanding economic benefits. It is also widely used to process juice, flour and food.

Working Principle

The materials enter into the pulverizing chamber from the upper feeding hole and the thin paste goes into the rotor center through the pipes on the right and left. Then the materials and thin paste will be dispersed around in the working chamber by means of centrifugal force and be impacted violently and repeatedly by a rotating needle and the fixed needle, which separates most of the starch and fibers. Because the fiber is sheared more lightly and incompletely during the impact, most of the fibers will be made into thin pieces. The materials processed by the percussive mills have a big proportion between the coarse dregs and the fine dregs, which is from 2.5:1 to 3:1. The starch can dissociate from the fiber piece to the greatest extent and the protein can dissociate from the starch more easily. The paste produced by the percussive mill can be discharged from the outlet and the fine milling process is finished.

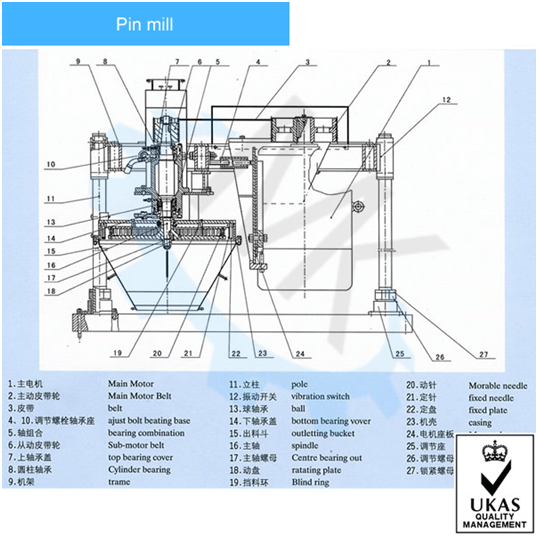

Structure

Characteristics of the equipment

1.Compact structure

2.Reliable running

3.Short process line

4.Good effect in Pulverizing

5.Strong processing ability

6.Good effect in sealing

7.Convenient installation and operation

Main technical specification

| 型号(Model) | 转子直径 Rotor dia(mm) | 转速 Rotation rate(rpm) | 进料量 Corn input(t/h) | 主电机功率 Main electric motor power(kw) | 外形尺寸 Overall dimension L*W*H(mm) | 重量Weight(Kg) |

| MKPM-685 | 685 | 4000 | 3~6 | 75 | 2300*1310*1760 | 1800 |

| MKPM-750 | 750 | 3580 | 5~7 | 90 | 2300*1310*1760 | 2000 |

| MKPM-1000 | 1000 | 3050 | 9~12 | 200 | 2850*1650*2240 | 4500 |