Fermentation Technology: Production Methods and Processes of Yeast Extraction

Post on 2025-02-24

1. Overview

The raw materials for manufacturing yeast extraction can include brewer's yeast, baker's yeast, Candida yeast, and lactic acid yeast, etc. On one hand, waste yeast from breweries can be used; on the other hand, yeast cells can be obtained through cultivation. The raw material sources are abundant and can be controlled according to the production volume. Generally, waste yeast sludge from breweries is used. Depending on the different forms of yeast raw materials, three different production methods are adopted for yeast extraction: autolysis method, enzymatic hydrolysis method, acid hydrolysis method, and mechanical disruption method (high-pressure homogenization method and high-speed ball milling method). These methods are also applied in small-scale production. This article mainly discusses the production process of yeast extraction by using the autolysis method.

2. Autolysis Production Process

The autolysis method utilizes the inherent enzymatic systems of yeast, such as glycosidases, proteases,nucleases,etc to break down the sugars, proteins, and nucleic acids within the yeast cells into smaller molecules such as amino acids, peptides, nucleotides, reducing sugars ,etc under controlled conditions with the addition of certain autolysis promoters. The raw material for the autolysis production process is fresh and active yeast with enzymatic activity, mainly baker's yeast from bread production and brewer's yeast as the by-product of beer brewing. Compared to the other two production methods, yeast extraction produced by the autolysis method has the high protein degradation rate, the high free amino acid content, good flavor, strong taste, and relatively low cost. Currently, the majority of yeast extraction produced in Europe, America, and China is made by using this method.

3. Production Process Flow

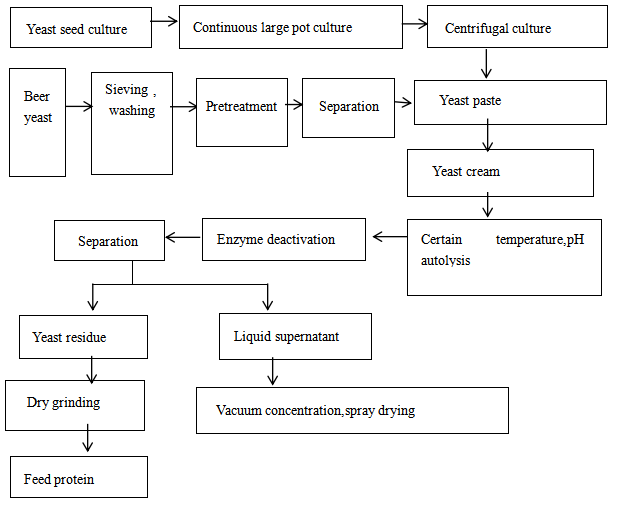

During the production process, by altering environmental conditions such as temperature, pH ,etc or adding certain autolysis promoters,which leads to the structure changes of the yeast cell membrane, releasing the large number of hydrolytic enzymes. At the same time, these enzymes are activated to degrade the macromolecular substances within the yeast cells. During the yeast autolysis process, due to the limited activity of the yeast's own enzymatic systems and the continuous decline in activity as the process progresses, the certain amount of proteases and nucleases need to be added externally to accelerate the autolysis of the yeast. The main process flow for producing yeast extraction using the autolysis method is shown in the below figure.

4. Specific Process

4.1. Screening, Washing and Separation

The raw beer yeast is mixed with water evenly, then washed by high-speed centrifugation to remove foam and beer flavor. It is filtered through a 200-mesh sieve to remove insoluble particle impurities in the yeast

sludge.

4.2. Pretreatment

Generally, raw waste beer yeast is treated multiple times with an appropriate concentration of sodium bicarbonate or alcohol, which can significantly improve the sensory quality of the extraction. The usage amount of sodium bicarbonate

is relatively small and it is added at 0.5% (mass fraction) for 2 hours ,which can effectively remove the bitterness caused by hop components, as well as other off-flavors and yeast flavors. The product has the strong fresh taste, with the rich flavor,

the harmonious taste, and the strong meaty aroma.

4.3. Adding Autolysis Promoters and Relevant Hydrolytic Enzymes

Adding autolysis promoters is mainly to activate the relevant hydrolytic enzymes within the yeast cells, promoting the autolysis process and shortening the production time. At the same

time, adding some hydrolytic enzymes after the autolysis begins or after a period of time can further facilitate the degradation of proteins and nucleic acids, and increase the extraction rate. Salt is one of the main solubilizers and also has the

functions of preservation and flavoring. Research reports indicate that when the salt concentration is below 2% (mass fraction) and the autolysis temperature is below 43℃, the autolysis solution is prone to spoilage. There is no significant difference

in color, aroma, taste, amino nitrogen yield, and total nitrogen content when the salt concentration is between 3% and 5% (mass fraction). However, the salt content must be considered in relation to the salt content of the final yeast extraction product.

When the salt content is above 5%, the taste of the final product is too salty. Generally, the salt content which is about 3% is more appropriate.

The key lies in controlling the process parameters of autolysis, such as temperature, pH, autolysis

time, the choice of autolysis water,etc. Yeast cells contain various proteases, and pH affects the activity of these enzymes, thereby influencing the degree of protein degradation and the quality of the product. When the initial pH of the autolysis

solution is above 8.5, yellowing and odorization are likely to occur during the autolysis process. The initial pH of the autolysis solution should be below 8.0. During the autolysis process, the pH naturally decreases. This is due to the acidic nature

of the spent yeast and the production of amino acids, especially acidic amino acids, from protein degradation. The initial pH of autolysis is 6 to 8, and by the end of the autolysis process, the pH of the autolysis solution can drop to around 5.5.

The initial pH of autolysis should not be too low. When the initial pH is adjusted to below 4.5 using hydrochloric acid or lactic acid, it is found that the content and yield of amino nitrogen in the product are relatively low. Generally, pH

of 6 to 7 is more suitable for the autolysis process.

Compared with autolysis using tap water, autolysis using distilled water results in the slightly better taste of the product with the rich and pure aroma, giving it an advantage in sensory quality. However, there is no significant increase in its content

and yield of amino nitrogen. When the amount of autolysis water is less, the yield of amino nitrogen in the product is lower, mainly due to the loss of yeast extraction on the yeast residue. When the amount of autolysis water is more, although the

content of amino nitrogen is lower, it is beneficial to increase the yield of amino nitrogen. Of course, when the amount of water used is larger, the concentration process of the product becomes more complicated. Generally, when the dry matter content

of the yeast slurry is around 20%, the amount of autolysis water should be about twice the weight of the yeast slurry. The autolysis temperature can be controlled at 40 to 60°C. The reason is that autolysis occurs at the low temperature below

35°C,which is not conducive to the action of proteases. Not only the content and yield of amino nitrogen in the product is low and the quality poor, but also the autolysis process is prone to spoilage and deterioration. The autolysis time should

not be too long. Products which autolyzed for more than 60 hours have the slight ammonia smell, indicating that excessive autolysis occurs. According to the change rule of amino nitrogen during the autolysis process, the autolysis time can be selected

to be around 40 hours.

During the autolysis of yeast, although certain glucanase systems have the certain hydrolytic effect on the cell wall, however,for most of the time, the cell wall remains relatively intact and has the function of a semi-permeable

membrane. Degradation products such as amino acids, low-molecular-weight peptides, and nucleotides can only be extracted through diffusion, which greatly limits the release of substances within the yeast cells and reduces the yield of the product.

Breaking the cell wall of yeast will increase the degree of cell wall disruption, promote the diffusion of intracellular degradation products, and increase the yield of the extraction. Additionally, it can induce and promote yeast autolysis to the

certain extent, enhance the action of the hydrolytic enzyme system, and shorten the autolysis process.

4.4. Enzyme Inactivation

After the autolysis process is completed, the temperature is rapidly raised to around 95°C and maintained for a period of time. This not only inactivates enzymes but also imparts the special meaty flavor to the final product

due to the occurrence of the Maillard reaction.

4.5. Separation

After enzyme inactivation, the mixture is cooled and centrifuged to obtain the autolyzed supernatant.

5. Conclusion

Overall, numerous scholars at home and abroad have conducted in-depth research on yeast autolysis and the production of yeast extraction,which continuously improves the production technology. The main quality indicators of yeast extraction products include amino nitrogen content, nucleotide content, flavor,etc. The yield of the extraction during the production process directly affects the production cost of the final product. Currently, a large amount of research is mainly focused on aspects such as yeast cell wall disruption, autolysis promoters, directed hydrolysis of yeast RNA, and removal of yeast flavor. These studies have significantly promoted the autolysis method for the production of yeast extraction.