Membrane Separation Technolog

Post on 2022-09-29

In the existing glucose production processes, starch is mostly used as raw material to obtain high-purity glucose through mixing, jet liquefaction, saccharification, plate frame or drum filtration, separation, and finally recrystallization. This traditional production process has the following disadvantages:

1. The regeneration of ion exchange resin needs to consume a lot of acid-base and water, and also produces a lot of acid-base wastewater;

2. the final products of glucose deep processing are fructose syrup, crystalline glucose and pharmaceutical grade glucose. The traditional process can only improve the purity by recrystallization to meet the high purity requirements of pharmaceutical grade glucose. Therefore, a large number of crystallizers and centrifuges are required, which not only has large investment and floor space, but also requires a large number of operators, and has low work efficiency and wage yield.

3. intermittent operation, low automation, low product quality and yield.

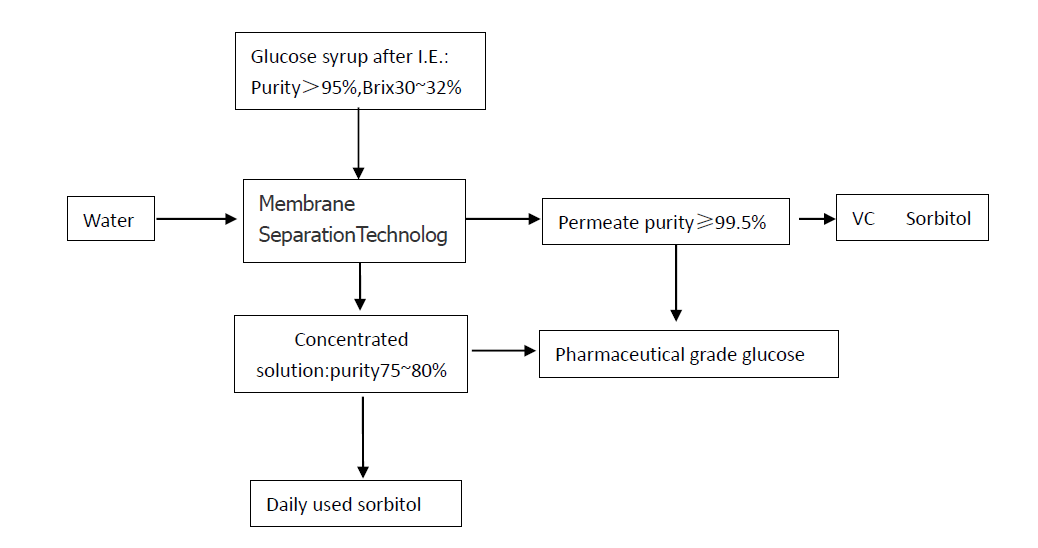

Membrane separation technology can ensure that the whole process can realize 24-hour continuous operation, and the product quality is stable and fully automated. The process flow diagram is as follows:

After membrane separation, the permeate has a high purity, up to 99.5%, and can be used to make VC grade sorbitol (this sugar solution does not need to be crystallized, and can be directly used to prepare high-purity sorbitol solution by catalytic hydrogenation) or medical grade glucose; The purity of concentrated liquid is low, about 75~80%, and it can generally be used to produce daily chemical grade sorbitol.