Hydrocyclone

Last update 2022-05-31

Application

Hydrocyclone used for starch washing, concentration and refining.

The main function of multi-stage hydro cyclone station is to remove the soluble and insoluble protein, fine fibers in starch slurry, it is the key equipment for starch concentration,

washing and refining.

Description

For each cyclone unit, it is comprised by starch pump and cyclone assembly. Series this kind of units combine into multi-cyclone stations, together to complete the refining work like concentrating, recycling and washing etc..

1.The washing system is mainly used for extraction of refined starch milk, removing of contained soluble and insoluble proteins and the possible small fiber.

2.Principles:Starch milk and wash water was the upstream way through the washing system, referring main flow chart of multi-stage cyclone separator system (Figure 8).Washing system usually consists of 6 to 12 stages .and each cyclone consists of several parallel-connected hydro-cyclone tubes.

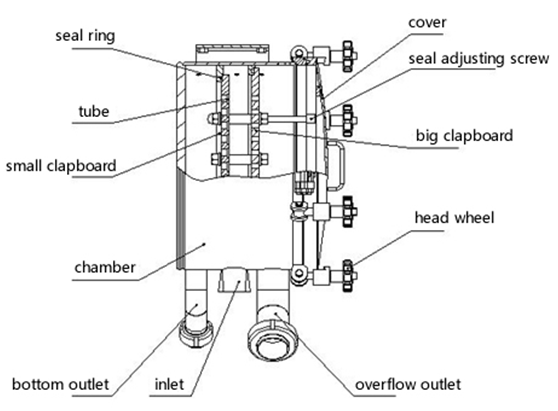

Each stage has feed interface, bottom stream interface and overflow interface.The bottom stream containing condensed milk, while the overflow containing soluble substances and small slag. The overflow of certain stage together with the bottom flow of previous stage is conveyed into the feeding bin of the middle stage. Starch milk is fed from first stage then conveyed through each stage in sequence, it is finally discharged from the last stage.

Overflow contains dilute starch milk and impurities to be removed. Washing water enters from feeding pump in the last stage and backflows in sequence until the first stage then finally overflows there, discharging the impurities such as protein small fiber residue.

Structure

Characteristics of the equipment

1.The equipment is made of stainless steel to prevent starch pollution;

2.The equipment surface is treated in a special process, beautiful and oil & dirt resistance;

3.The swirl tubes are made of special nylon, high-energy and high efficiency.

4.The

multistage hydro cyclone station combines concentration, recovery washing and fine slag separation functions in one

5.The device features simple and reasonable design, beautiful appearance and stable quality, easily maintenance.

Main technical specification

| Model | MKHC205 | MKHC250 | MKHC275 | MKHC300 | MKHC350 | MKHC405 | MKHC425 | MKHC450 | MKHC505 | MKHC550 | MKHC600 | MKHC650 | MKHC700 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flowrate(m³/h) | 12.5 | 25 | 30 | 40 | 50 | 70 | 86 | 100 | 135 | 155 | 230 | 300 | 450 |

| Starch output(tpy) |

5000 | 10000 | 15000 | 20000 | 30000 | 40000 | 50000 | 60000 | 80000 | 100000 | 150000 | 200000 | 300000 |

| Feeding pre.(Mpa) |

0.6~0.8 | ||||||||||||

| tubes dia.(mm) |

10 |

||||||||||||

| Unit power(kW) |

5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 45 | 55 | 75 | 90 |

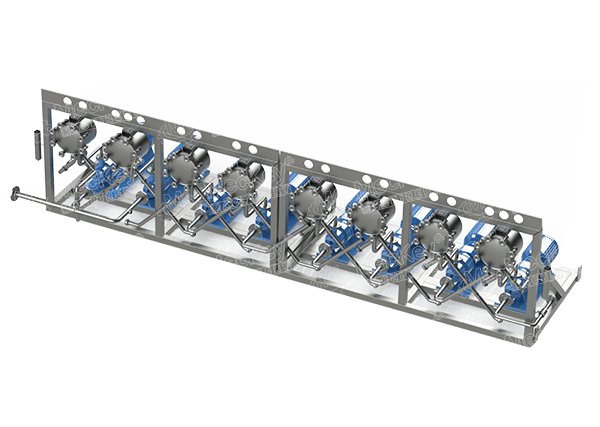

Site photo